The advantages of Laser welding

With our high-power, robust laser welding machines, you have at your disposal a machine that makes complicated joints possible, that would otherwise, with classical joining techniques, be difficult if not impossible to realize. Even in the immediate vicinity of sensitive materials such as plastic or glass, weldings are made possible. The excellent controllabilty of laser energy and the exposure time to the material allows for welding of metallic materials with high melting points and of high conductivity. Even different metal types can be joined.

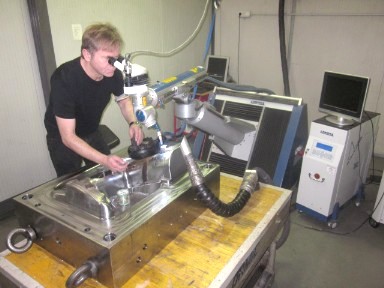

Repair welding on plastic mould

Laser welding: manifold > time-saving > economical

- exact processing, even on the finest structures, with pin-point accuracy and precise energy-input

- The exact geometry of the workpiece remains the same, within the material tolerances. Only extremely slight distortions may take place on the workpiece, which can be disregarded.

- Only very minimal changes of the microstructure take place, due to the limited heat-affected zone.

- Welding results without burning grooves. The quality of the adjacent areas of the material remains unaffected.

- Process safety and a high degree of reproducibility of laser weldings.

- The welding seams are free of shrinkage cavities and binding flaws, so that a high quality result is achieved.

- Pre-warming is almost never necessary, even in the case of workpieces which are prone to tears.

- The welding material properties can be specifically influenced. The choice of laser parameters and of welding additives affect the mechanical properties of the welding material, such as hardness, tensile strength or elongation.

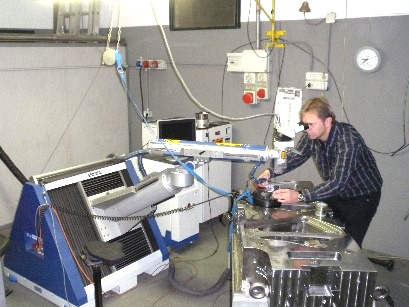

Deposit welding on large surfaces

Lasers can be used in various areas of manufacture and repair. Major areas of application are:

Precision engineering:

Welding precision metal parts

Die and mould-making:

Repairing surface defects and voids in everything from small moulds to massive dies

Medical technology:

Welding surgical instruments, passive and active implants, and endoscopic components

Sensor technology:

Welding of thermal elements, measuring sensors and pressure membranes

Sheet metal work:

Welding enclosures for electronic equipment, stainless steel parts for domestic appliances, architectural components and sculptures

Weldable materials

- High alloy cold- and hot-working steels

- Bronzes and copper alloys

- Stainless steels

- Steel and grey cast-iron alloys

- High-tensile aluminium alloys

- Titanium alloys

- Nickel

- Precious metals, e.g. platinum, gold and silver

Different Laser applications

The possible applications of Laser welding are very various. That's why we offer our customers complete solutions, for specific demands, from one source.

- specific welding filler metals

- Laser welding systems

- metallurgy

- welding trainings

- qualified service

- assistance in welding problems

- telephone accessibility seven days a week